There are 4 Types of Testings in any Pumps

Hydrostatic Pressure Test

Mechanical Strength Test

Pump Performance Test

Wetted Part's Chemical Composition Test

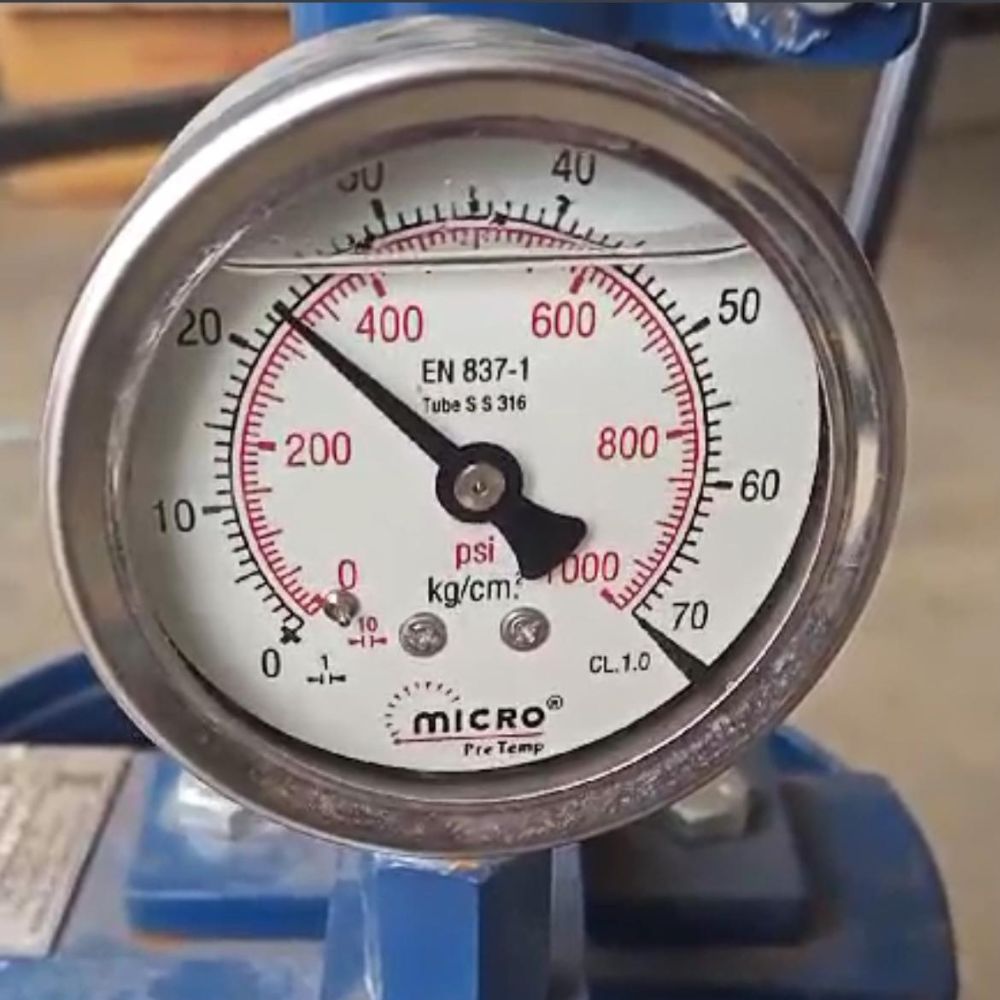

Hydrostatic Pressure Test

According to the standard of the manufactured pump, we are performing this test for 100% of the pumps that are dispatched from our factory with the help of a calibrated hydrostatic pressure test system. This test prevents liquid end kit leakage and mechanical seal or gland packing leakage problems.

Mechanical Strength Test

Each and every one of our casting parts is tested for mechanical parameters like tensile strength, yield strength, elongation, and local hardness. This test helps to maintain the mechanical strength of the pump.

Pump Performance Test

We have a pump performance testing facility according to the Hydraulic Institute in the United States, and we are performing pump performance tests according to the customer's request. This ensures:

Customers are confident in the pump's performance.

A good understanding of how much performance the pump has.

Wetted Part's Chemical Composition Test

We are conducting material test certificates for each casting to ensure that our customers are receiving:

The proper chemistry of exotic materials for construction.

Proper wear resistance against corrosive chemicals and fluids.