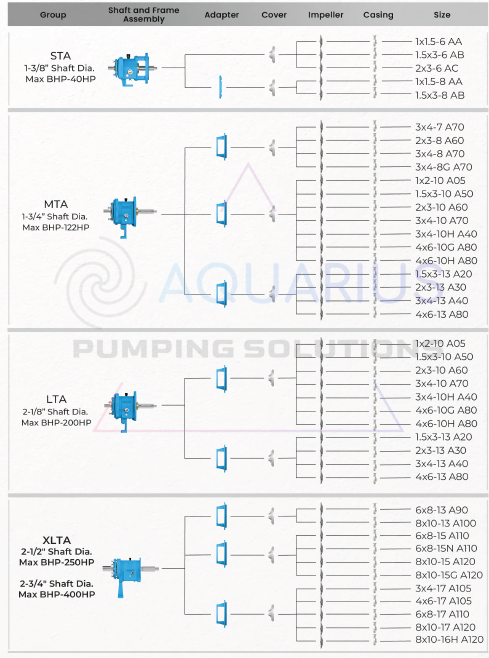

Specifications

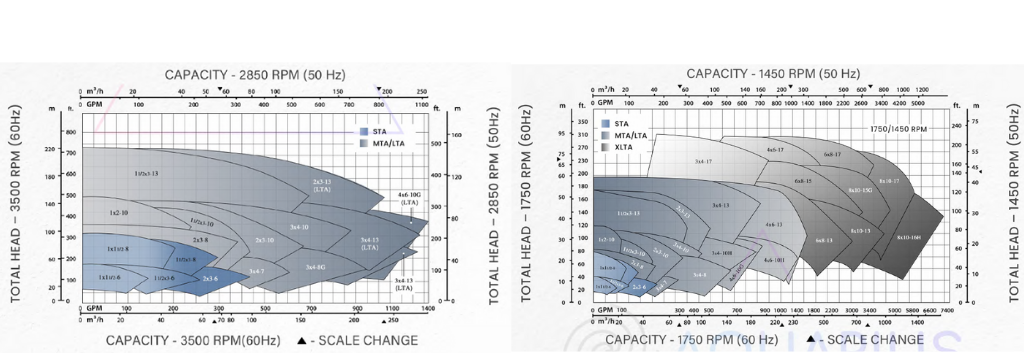

Capacities : Up to 7000 GPM (1590 m³/h)

Heads : Up to 730 feet (223 m)

Temperatures : Up to 700° F (371° C)

Pressures : Up to 375 PSIG (26 bar)

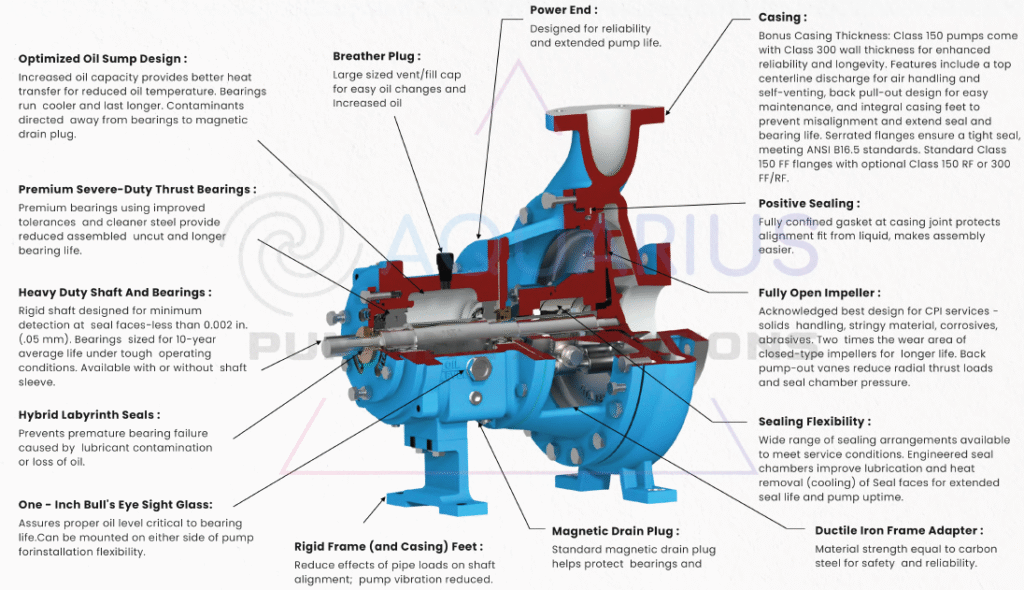

Aquarius A196 Series comply with ASME/ANSI B73.1M Standard Open Impeller Design.

Aquarius A196 Series is Directly interchangeable with reputed ITT Goulds© 3196 Series and many other ANSI Pump Manufacturers’ ANSI Pump Series.

Aquarius A196 Series can be used in variety of Process Applications as it is having options in MOC of wetted parts like Iron, Carbon Steel, SS316, Cd4MCuN, Alloy20, Monel, Nickel, Hastelloy C276, Titanium, etc.

Various industries like Petrochemical, Chemical, Primary Metal, Pharma, Food & Beverages, etc. can use Variety of Sealing options and All API Sealing Plans in Aquarius A196 Series Process Pumps.

Capacities : Up to 7000 GPM (1590 m³/h)

Heads : Up to 730 feet (223 m)

Temperatures : Up to 700° F (371° C)

Pressures : Up to 375 PSIG (26 bar)

Precision-machined open impeller adheres to ANSI B73.1M and enables direct OEM component replacement without modification.

Precision-machined open impeller adheres to ANSI B73.1M and enables direct OEM component replacement without modification.

Dynamic Sealing:

Dynamic Sealing:

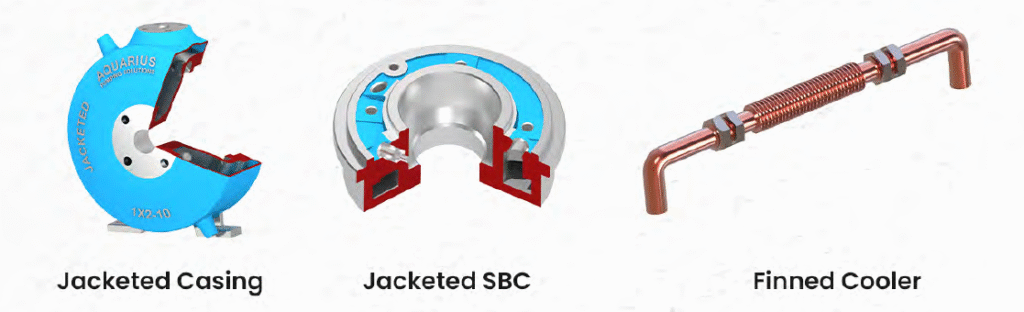

High Temperature application

Finned Cooler: Directly cools oil for lower bearing temperature. Requires minimum cooling water. Corrosion resistant construction. Recommended for temperature over 350° F (177° C) Jacket stuffing box: Keep proper temperature control of sealing environment. Perfect for polymerizing liquids. Jacketed casing: Ideal for heating or cooling pumpage.

Maintenance optimization feature

Back pull out assembly, External impeller axial adjustment, high parts interchangeability, C-face motor adapter (optional)

Safety Features

Heavy duty casings are designed with higher wall thickness, all pressure retaining components are 100% hydrostatic tested, coupling guards comply with ANSI B15.1 standard, Optional shaft guard on adapter.

| Specification | 4 Pole Motor | 2 Pole Motor |

|---|---|---|

| Capacity | Up to 7,000GPM (1,590m³/h) | Up to 1,400GPM (318m³/h) |

| Head | Up to 300ft (92m) | Up to 730ft (223m) |

| Temperature | Up to 700°F (371°C) | Up to 700°F (371°C) |

| Pressure | Up to 142PSIG (979KPa) | Up to 375PSIG (2,586KPa) |