Specifications

- Capacities to 2700 GPM (610 m3/h)

- Heads to 440 feet (134 m)

- Temperatures to 500°F (260°C)

- Pressures to 285 PSIG (1965 kPa)

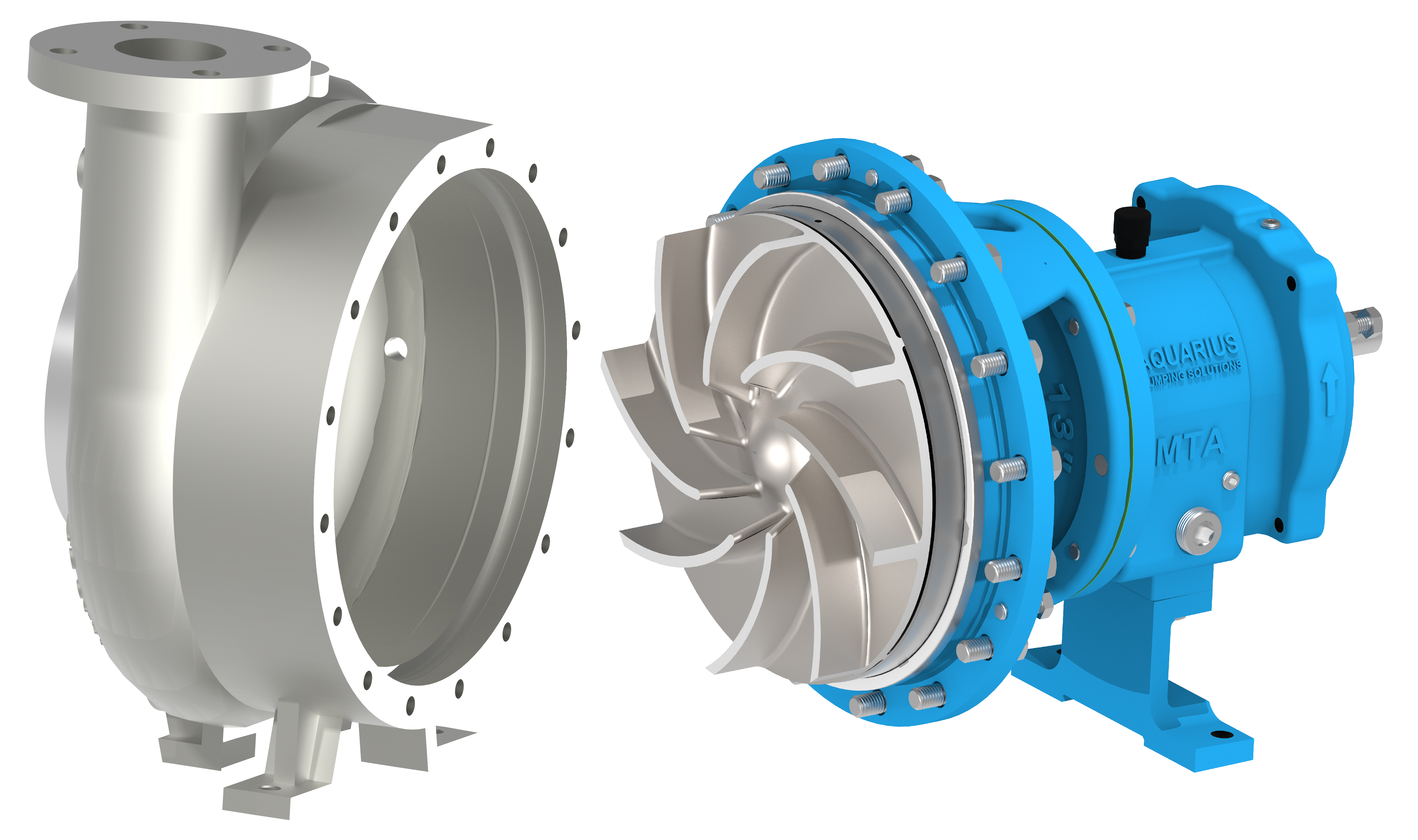

Aquarius A196-CV Series comply with ASME/ANSI B73.1M Standard Non-Clogged Recessed Impeller Design.

Aquarius A196-CV Series is Directly interchangeable with reputed ITT Goulds© 3196CV Series and many other ANSI Pump Manufacturers’ ANSI Pump Series.

Aquarius A196-CV Series can be used in variety of Non-Clogged Process Applications as it is having options in MOC of wetted parts like Iron, Carbon Steel, SS316, Cd4MCuN, Alloy20, Monel, Nickel, Hastelloy C276, Titanium, etc.

Various industries like Petrochemical, Chemical, Primary Metal, Pharma, Food & Beverages, etc. can use Variety of Sealing options and All API Sealing Plans in Aquarius A196-CV Series Non-Clogged Process Pumps.

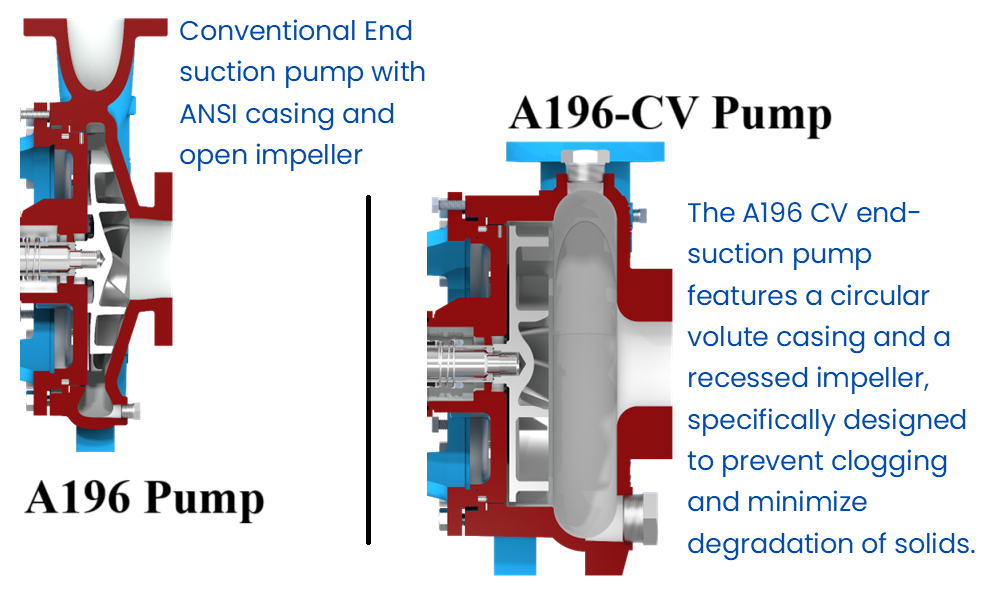

For pumping a Fluid which contains bigger sized Solid Particles and Fibrous Material Handling Application, Aquarius A196-CV Series Pump Circular Vortex type Casing and Recessed type Open Impellers provide Non-Clogging capability with minimal Solid Degradation. If fluid is having Air or Gas, Aquarius A196-CV Pump Series can handle this easily.

…

..

…

…

…