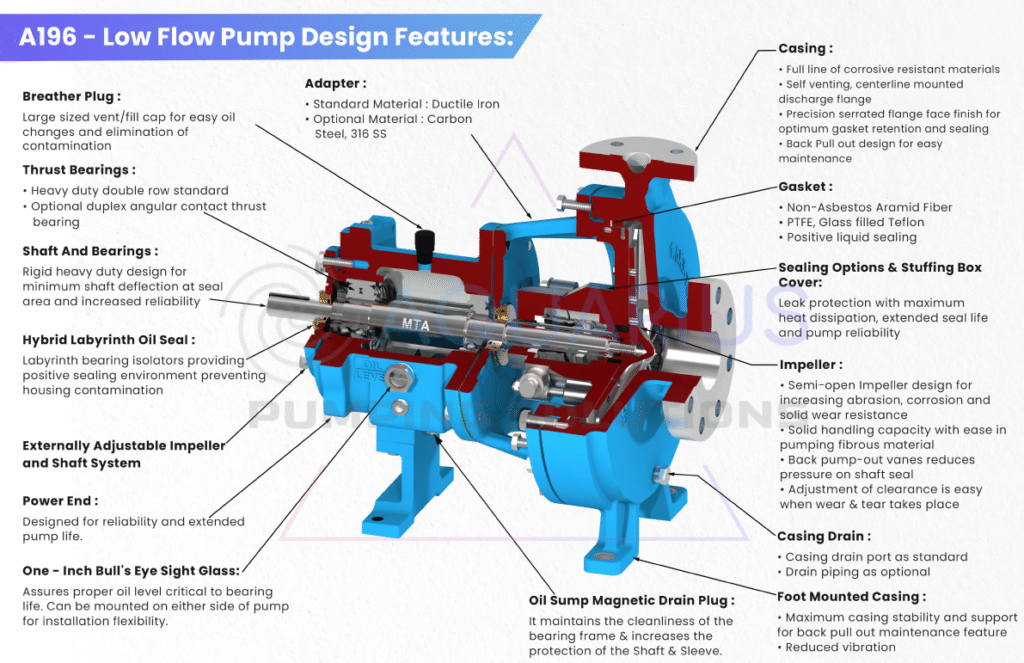

Specifications

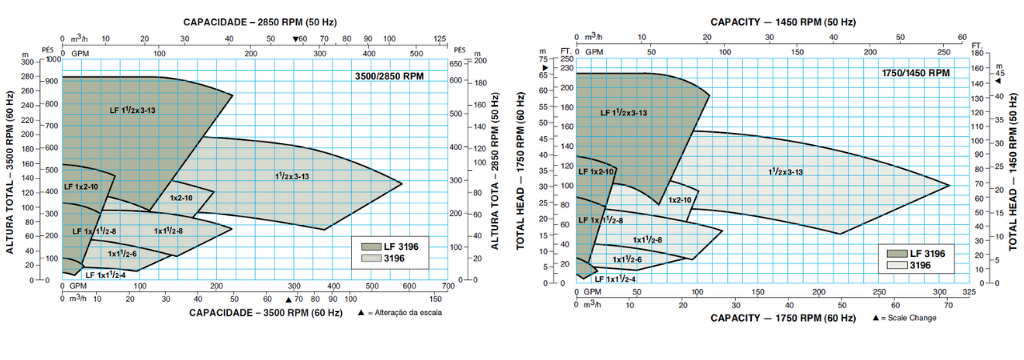

Capacities : Up to 220 GPM (50m³/h)

Heads : Up to 925 feet (282 m)

Temperatures : Up to 700° F (371° C)

Pressures : Up to 450 PSIG (31 bar)

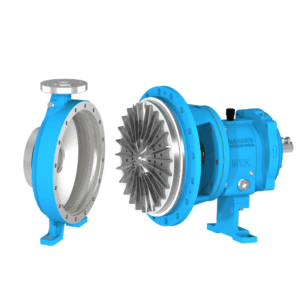

Aquarius A196-LF Series comply with ASME/ANSI B73.1M Standard Open Impeller Design.

Aquarius A196-LF Series is Directly interchangeable with reputed ITT Goulds© 3196LF Series and many other ANSI Pump Manufacturers’ ANSI Pump Series.

Aquarius A196-LF Series can be used in variety of Low-Flow Process Applications as it is having options in MOC of wetted parts like Iron, Carbon Steel, SS316, Cd4MCuN, Alloy20, Monel, Nickel, Hastelloy C276, Titanium, etc.

Various industries like Petrochemical, Chemical, Primary Metal, Pharma, Food & Beverages, etc. can use Variety of Sealing options and All API Sealing Plans in Aquarius A196-LF Series Process Pumps.

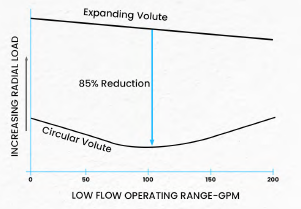

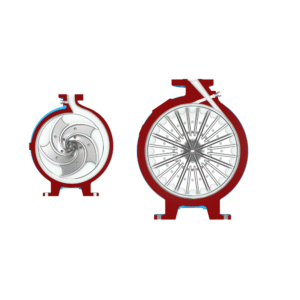

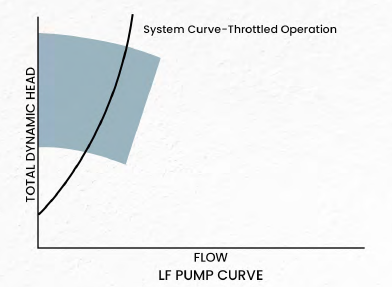

For Low Flow Application, If we throttle regular centrifugal pump then Seal Chamber pressure and Axial Thrust on Bearings will increases and Seal-Bearings will fail in short period of time. Aquarius A196-LF Series pumps are having Circular Volute and Radial Vane Design to eliminate all above problems.

Capacities : Up to 220 GPM (50m³/h)

Heads : Up to 925 feet (282 m)

Temperatures : Up to 700° F (371° C)

Pressures : Up to 450 PSIG (31 bar)

Low flow Impellers designed per ANSI B73.1M standard, ensuring dimensional interchangeability with OEM low-flow configurations.

Engineered specifically for low-flow application, these end suction pumps minimize radial loads and shaft deflection-enhancing bearing and seal life while reducing downtime and maintenance costs.

Reduces radial loads by up to 85% vs traditional expanding volute designs under low-flow conditions, significantly improving bearing life, seal reliability, and pump longevity.

A196LF is engineered for stable performance under throttled low-flow conditions, featuring a concentric volute and open radial vane impeller to reduce hydraulic instability, radial loads, and mechanical stress.

Dynamic Sealing: ideally used for corrosive and slurry application, eliminate need for mechanical seal, no need for seal cooling water, Utility cost is reduced, less expensive than a slurry mechanical seal

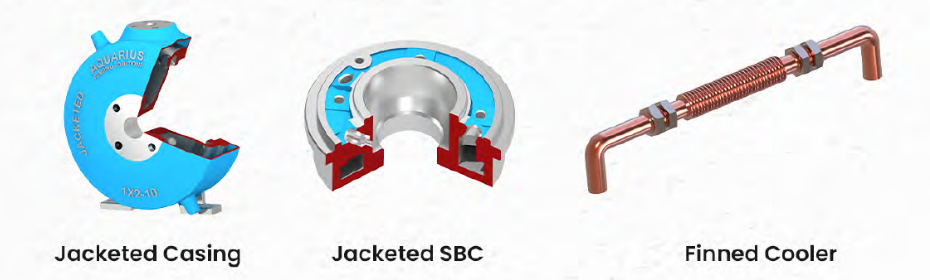

Finned Cooler: Directly cools oil for lower bearing temperature. Requires minimum cooling water. Corrosion resistant construction. Recommended for temperature over 350° F (177° C)

Jacket stuffing box: Keep proper temperature control of sealing environment. Perfect for polymerizing liquids.

Jacketed casing: Ideal for heating or cooling pumpage.

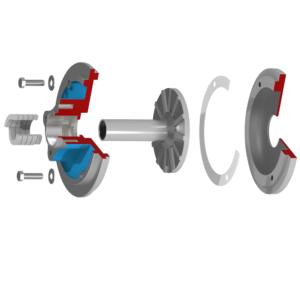

Back pull-out design allows maintenance without disconnecting piping or motor.

Interchangeable components reduce spare parts by matching A196 pump parts.

External impeller adjustment enables precise clearance setting without disassembly.

Retrofit ready design ensures direct installation into existing pump systems.

ANSI B15.1-compliant coupling guard ensures personnel protection against rotating components.

Ductile iron frame adapter provides enhanced structural integrity and impact resistance.

Raised face flanges allow secure, pressure-tight connections per ASME standards.

Optional shaft guard offers additional protection from shaft exposure in critical application

| Specification | 2 Pole Motor | 4 Pole Motor |

|---|---|---|

| Capacity | Up to 220GPM (50m³/h) | Up to 101GPM (23m³/h) |

| Head | Up to 925ft (282m) | Up to 213ft (65m) |

| Temperature | Up to 700°F (371°C) | Up to 700°F (371°C) |

| Pressure | Up to 450PSIG (3,102KPa) | Up to 450PSIG (3,102KPa)* |

…